Without consistent belt tracking, your conveyors can succumb to misalignment, leading to accelerated wear and tear, potential costly damage to the belt, operational halts and reduced safety.

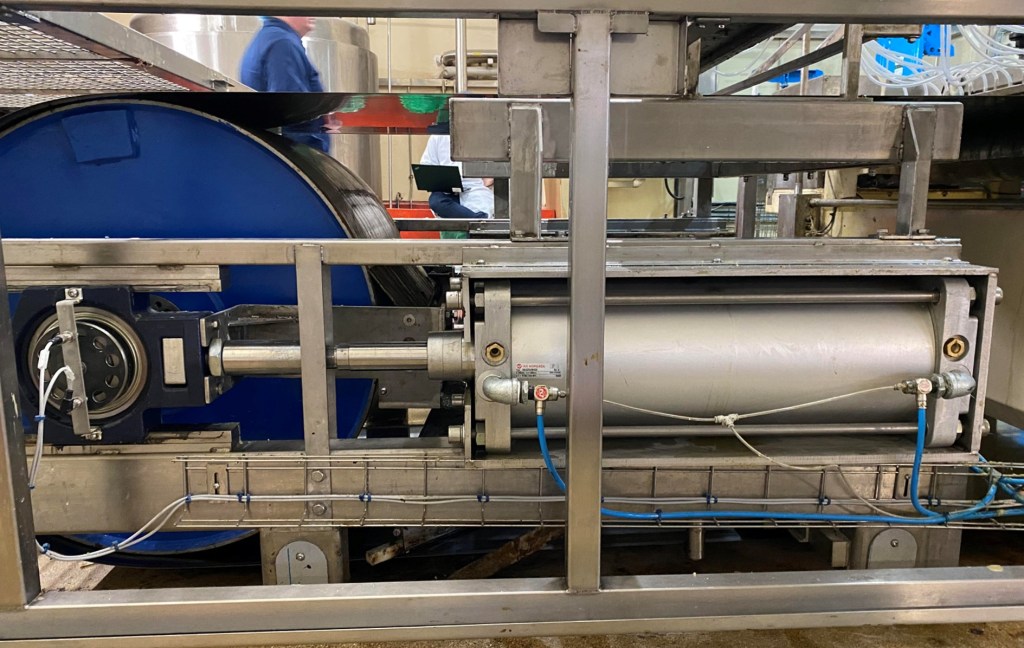

Our in-house design studio is proud to have developed the in-feed tensioning tracking system. This pneumatic belt tracking control and tensioning system for bake ovens, conveyors, coolers and other steel belt installations has been proven to extend belt life significantly and has been safeguarding investments in belts for the past decade.

A stable belt position allows full utilisation of the belt width, maximising production and reducing waste. Hazards are reduced not only by stabilising the belt position throughout its conveyor, but also by preventing product being laid down on the band edge and therefore at risk of falling off and posing a risk.

Our system is unique due to the state-of-the-art belt positioning sensor, used to continuously detect the belt position in real time. The positioner provides low input voltage signal to our state-of-the-art PLC, which in-turn activates any required correction to the lateral position of the belt.

The belt positioning sensor is fully submersible and resistant to dirt and has no electrical contact across the transducer positioning element – meaning clean data, infinite resolution and a very long life. Belt tension always remains applied by the system, even in the event of sudden loss of power or air supply, whilst maintaining belt tension through thermal expansion and retraction.

All-British designed and manufactured and built to CE specification, our system provides reliable and high precision tracking to (+/-) 0.1 mm, under different environmental and running conditions.

The system steers the in-feed drum via two heavy-duty pneumatic cylinders and will track the belt to (+/-) 3mm at the in-feed, giving superb stability and repeatability, whilst maintaining correct tension on the oven band.

We design the system to incorporate accessible bearings for ease of maintenance, a removable drum shaft and a state-of-the-art PLC control panel with touch-screen colour HMI display.

Replacing your current in-feed frame, drum and bearings with our design does away with the reliance on heavy-duty springs, which are proven to be a health and safety problem.

For more information on how our products and services can help optimise your productivity, read our brochure.